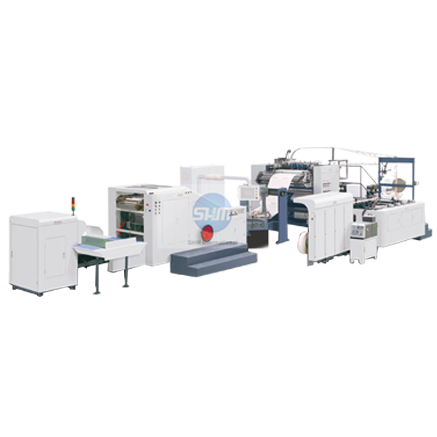

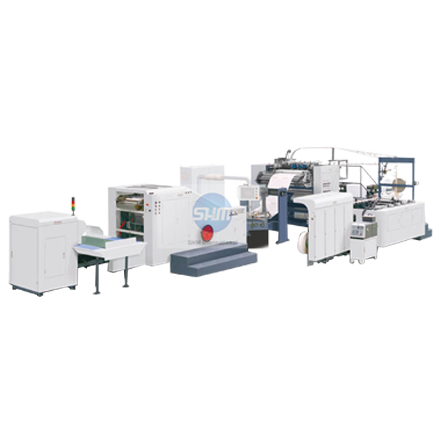

ZD-QFJ08 Fully Auto Roll-fed Square Bottom Paper Bag Machine

This machine is designed to manufacture square bottom paper bags with handles from paper roll, paper patch roll and paper rope, and it is an ideal equipment for producing paper handbags fast. By implementing steps including handle making, handle application, tube forming, tube cutting and bottom forming within a fully automatic process, this machine can effectively save labor costs. The equipped photoelectric detector can correct cutting length, so as to ensure cutting precision. SIEMENS PLC system and adjustable dual-moulds structure, ensure that the machine can perform quickly and stably, as well as reduce adjusting time for different bag sizes. Special bags collection platform and counting function, improve packing efficiency of paper bags packing. Thanks to perfect technologies and fast production speed, this machine can produce paper handbags with high quality in many different forms, which are especially suitable for food and clothing industries.

| Paper roll width | 410-770mm (310-750mm) |

| Max paper roll diameter | 1200mm |

| Material core diameter | 76mm |

| Paper thickness | 50-140gsm |

| Bag body width | 140-220mm (90-220mm) |

| Paper tube length | 230-370mm (220-470mm) |

| Bag bottom size | 50-140mm |

| Handle rope height | 80-85mm |

| Handle rope diameter | 4-6mm |

| Handle patch length | 114.3mm |

| Handle patch width | 45-50mm |

| Paper patch roll diameter | 1200mm |

| Paper patch roll width | 90-100mm |

| Paper patch thickness | 100-180gsm |

| Max speed | 150bags/min (220bags/min) |

| Power | 28kw |

| Weight | 15000kg |

| Dimension | 11000x4400x1800mm |