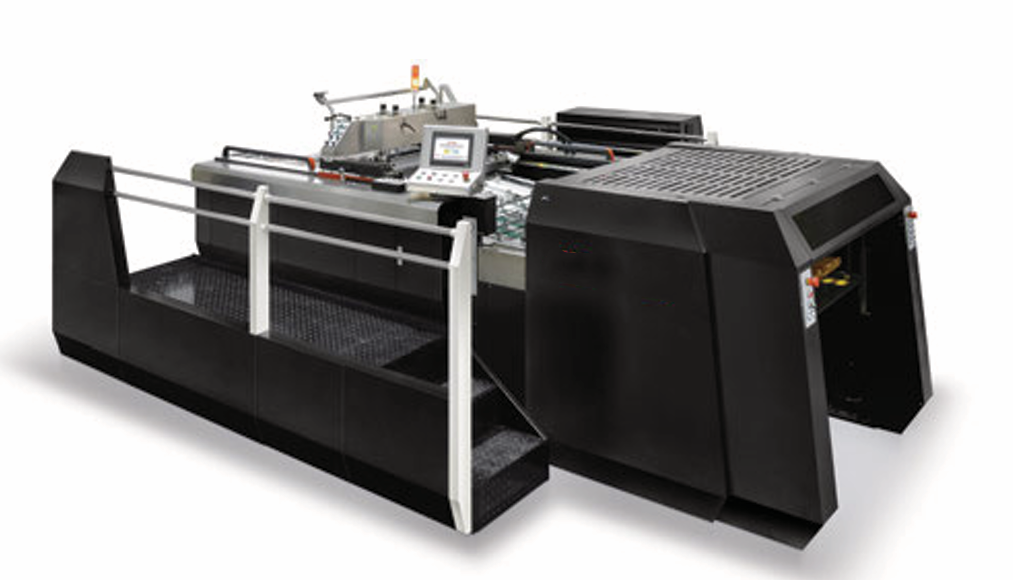

JB-106C Servi Druven Full Automatic Stop Cylinder Screen Press Automatic Cold Foil Application Machine

JB-106C Intelligent SERVO control automatic STOP screen printing machine

It is an industry-leading product with a number of invention patents and utility modelpatents. Under the requirement of ensuring the quality of printed products, the full-size printing speed can reach 4200 pieces / hour. If you choose to print personalized products, the speed can reach 4500 pieces / hour. It is the best choice for today's paper and plastic boutique packaging, ceramics and glass decals, textile transfer, plastic film switches, electronic and electrical related components and other industries.

The machine abandons the traditional single power source with transmission shaft,gearbox, chain and crank, and then drives the four moving bodies of Feida, conveying, roller and mesh frame. Three servo motors are used to drive the paper feeding conveying, roller and frame respectively. Through automatic control, the synchronization of several functional units is ensured, which not only eliminates a large number of mechanical transmission parts, but also greatly improves thestiffness of printing machinery, It reduces the error caused by the mechanical transmission device, improves the printing quality and mechanical efficiency, improves the automation level of the production process, and improves the working conditions of the environment

| JB-1050SGL Cooling section | |

| Cooling system | Water cool |

| Max speed | 60m/min |

| Power of convey motor | 400w |

| The lowest temperature | 15 |

| Cooling section power | 5HP 5.54kW |

| Fan power | 1.1kW |

| Weight | 900kg |

| Overall dimension | 2100 x 2200 x 1580mm |

| JB-1050SG Full automatic stacker | |

| Max sheet size | 1100 x 750mm |

| Min sheet size | 350 x 250mm |

| Pile height | 900mm |

| Top speed | 5000pcs/h |

| Power | 380V 50Hz 0.92kW |

| Total weight | 700kg |

| Overall dimension | 2700 x 2050 x 2750mm |

| JB-106C Servo control screen printing press | |

| Max sheet size | 1060 x 750mm |

| Min sheet size | 560 x 350mm |

| Max printing size | 1050 x 750mm |

| Screen frame size | 1300 x 1170mm |

| Sheet thickness | 90-50g/m |

| Border | <10mm |

| Printing speed | 500-4500sheet/h |

| Installation power | 3P 380V 50Hz 31kW |

| Weight | 4600kg |

| Overall size | 4850 x 4220 x 2050mm |

| JB-106XH Snow UV curing machine | |

| Convey speed | 75m/min |

| UV lamp power | 10kW x 4pcs |

| Wrinkle lamp power | 40w x 5pcs |

| IR lamp power | 1.5kW x 3pcs |

| Effeciency curing width | 1100mm |

| Convey motor power | 400w x 2 |

| Vaccum fan power | 1.1kW front 2.2kW back |

| UV exhaust fan | 0.37kW x 4 |

| Small exhaust fan | 40W x 7 |

| Total power | 3P 5Lines 380V 50Hz 90 A |

| Weight | about 2150kg |

| Overall size | (6315+660) x 1950 x 1770mm |