KYD-950+ Automatic row stripping machine

As an innovative solution for post-die-cutting processes, this equipment integrates automatic waste removal, product collection, and scrap discharge in one system. With advantages including easy set-up, small footprint, high output,and low eclectic cost. It is ideally suited for hang tags, labels, paper cups, pharmaceutical packaging, cosmetic packaging, and so on. The system effectively reduces labor costs, enhances product quality, and boosts production efficiency through intelligent automation.

| Max material stack size | 950 x 950 mm |

Max stack thickness | 80 mm |

| Mini stack thickness | 60 mm |

| Max product size | 930 x 280 mm |

| Mini product size | 90 x 60 mm |

| Max pressure | 50kN |

| Speed | 4 Times/min |

| Total power | 11kW |

| Average power | 5.5kW |

| Air consumption | 15L/min |

| Working air press | 0.5-0.6Mpa |

| Voltage | 380V 50/60Hz 3phase |

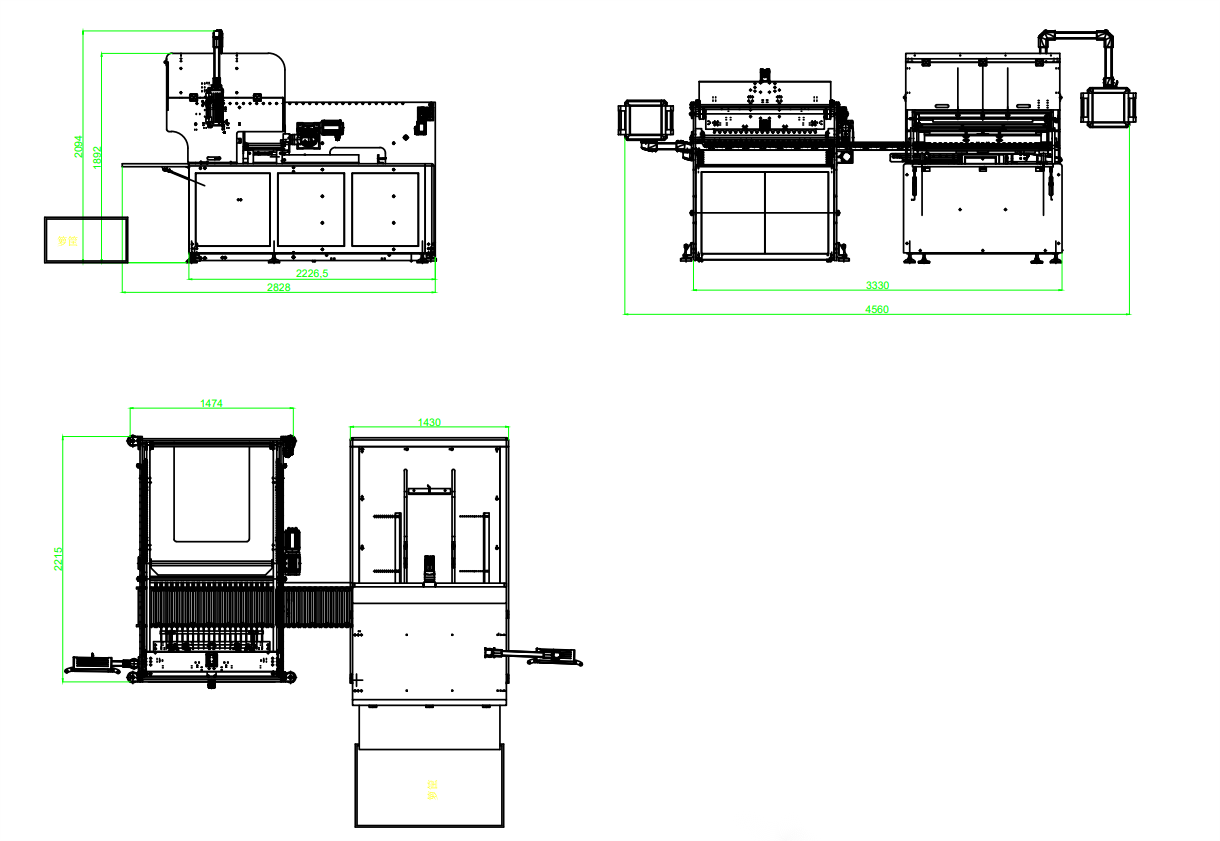

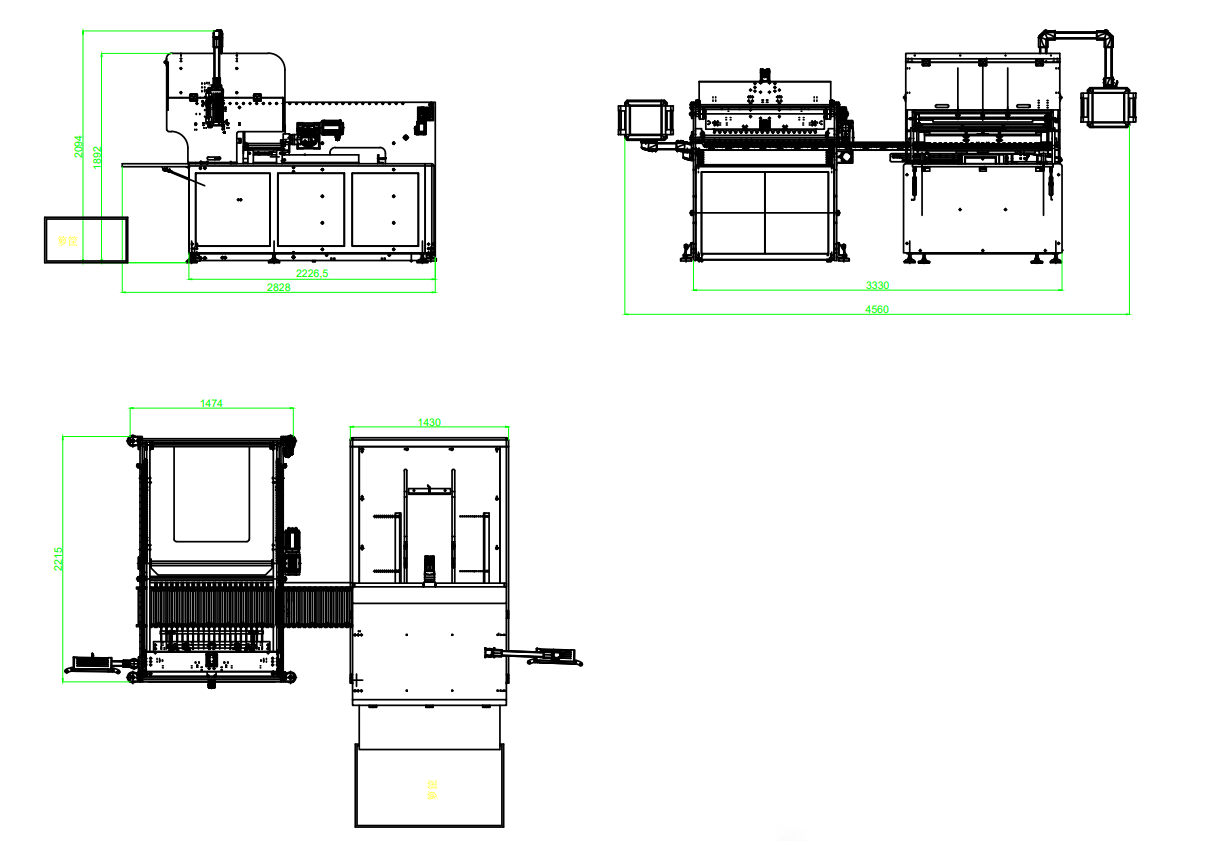

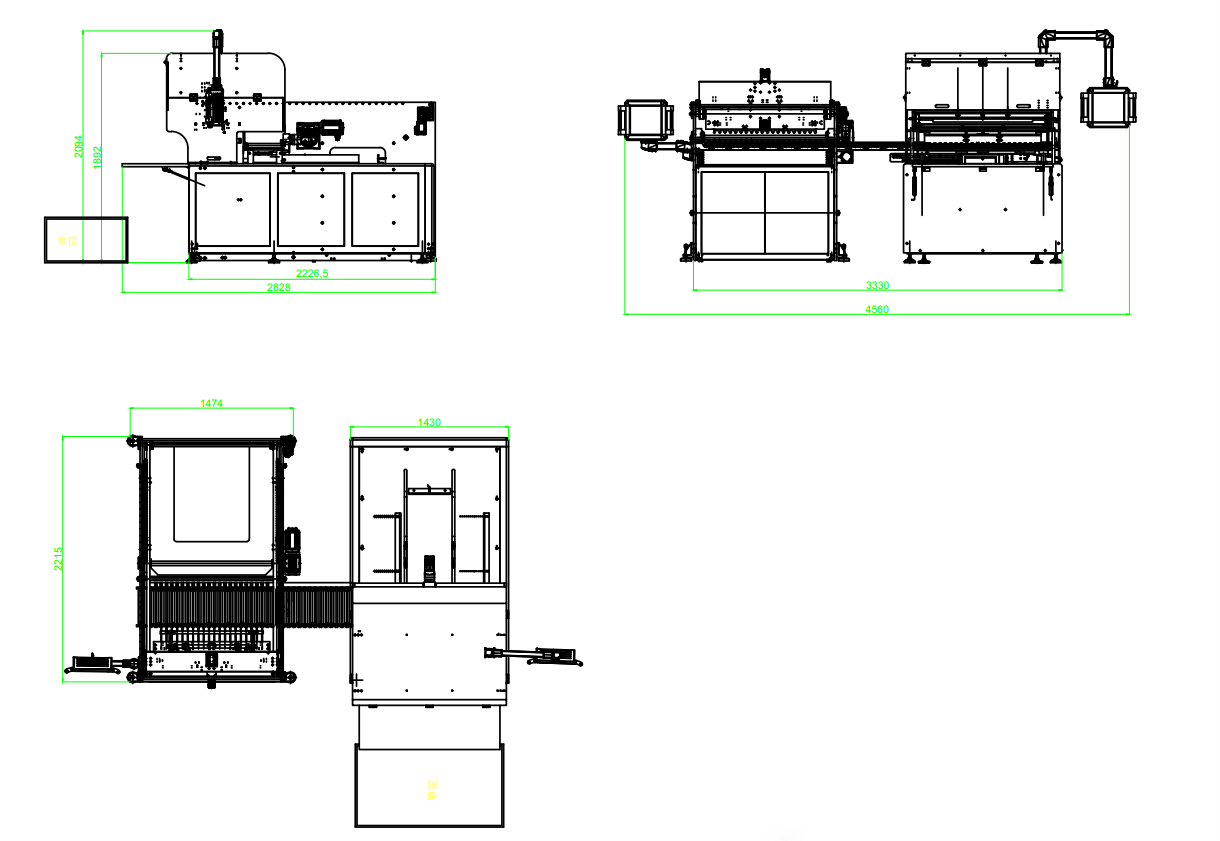

| Machine size | 2820 x 3400 x 2100mm |

| Weight | 3440kg |

-

Palletizing Air control part

-

Host Air control part

-

Palletizing electrical parts

-

Host electrical parts

-

Aluminum rollers in the palletizing area, connected to the main machine

Servo motor: 0.75kw

-

Auto palletizing part with auto lifting

Save time and labor costs

Palletizing height: 1M

-

Rotating Touch Screen

(1 for host machine, 1pc for Auto palletizing part ) to operate machine, easy adjust machine and set new data working

-

Servo-controlled aluminium rollers ensure product transfer to the conveyor table stably.

Deliver servo motor: 0.75kw

-

Upper Pressing plate press on the waste part and Lower Pins to support the products part.

Mini waste gap: 3MM

-

Servo motor and ball screw ensures a precise pile positioning

Feeding servo motor: 1.5KW

-

Vane type hydraulic pump with cooling fan giving the stable working pressure.

Oil Tank Volume: 60L

Motor: 3.75KW